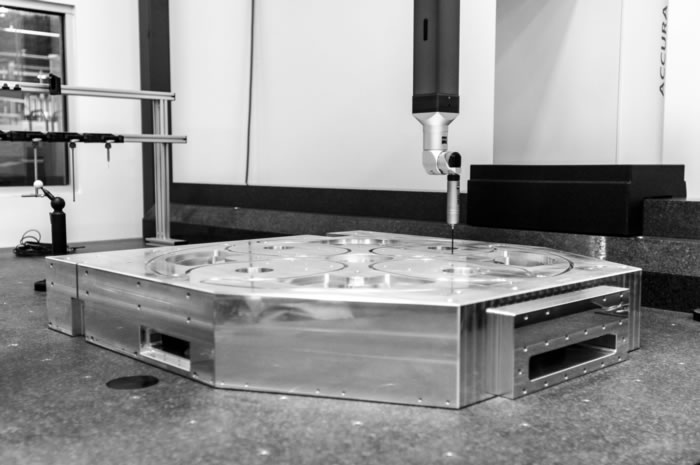

Carl Zeiss Contura G2

The CONTURA G2 is a mid-range bridge type CMM with advanced features and design strengths. All axes have 4-sided Carl Zeiss air bearings providing maximum stability and very precise measurement.Ceramic guideways are thermally stable, minimizing the effect of temperature variation. The CONTURA G2 is available in two versions, RDS and aktiv, each designed for specific application requirements.The RDS option incorporates the Zeiss articulating probe holder and is suitable for measuring multiple angles and where small styli are required. Over 20,000 angular positions can be reached in 2.5° increments and measurements are done using the VAST XXT probe.The aktiv version incorporates the VAST XT active scanning probe and is used for measuring deep features, reference systems, position errors and for high throughput applications. Other probe options are available for both CONTURA G2 models (see below). Measuring volumes range from 700x700x600mm to 1000x2100x600mm. Temperature range 18 to 22°c (18 to 26°c with HTG option).

Features:

» High specification granite base

» Highly accurate C99 controller

» Computer aided error correction

» Dual control joysticks

» CALYPSO metrology software

» Optional multi-sensor change rack

» Optional CMM and workpiece temperature sensors (HTG)